ADT Haul Truck Scales

Haul Truck Scales

Why equip your Rigid Dump Truck or ADT with VEI Payload Monitoring?

- Load right on the spot

- Reduce truck wear: tyres, transmission, engine & bodywork

- Production Monitoring in real time on your tablet, smart phone or PC

- Know beforehand the transported cost per ton

- Track loading efficiency

- Reduce fuel consumption by preventing overloading

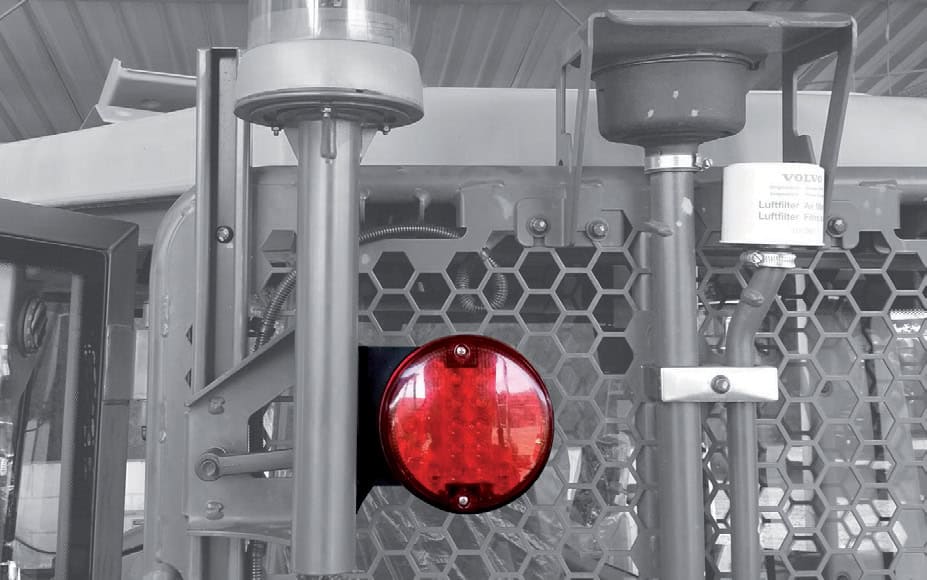

EXTERNAL LIGHT FOR MAXIMUM CAPACITY WARNING

This LED light is installed outside the cabin to alert the loading machine when the maximum capacity is about to be reached. With an intermittent flashing which increases when the set threshold is approaching, it proves to be useful for the load phases where compliance with the capacity of the vehicle represents a decrease in maintenance costs. Up to 3 lights can be installed to compensate for the different loading positions that the machine can take, right, left or back.

iPOTWEB Real-Time Cloud Loadout Reporting

YOUR LOADS

The Loading Movements page displays your loads and events such as machine’s scale switch on and off and when the Zero at Empty has been done.

Having different tools available, filters can be set, delivery dockets be printed, exports can be done in different formats. A find function can be sued to find out what you need to look, export or print.

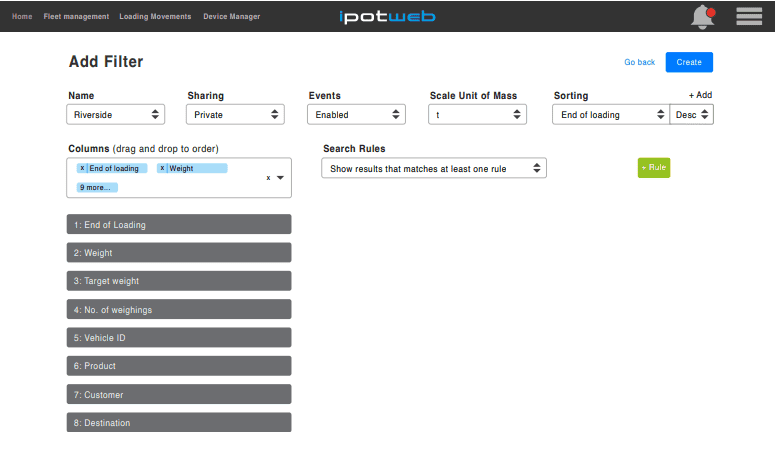

FAVORITE FILTERS

Setting different filters makes your

movements table flexible just with one click allowing to display print and export your valuable data in a matter of seconds

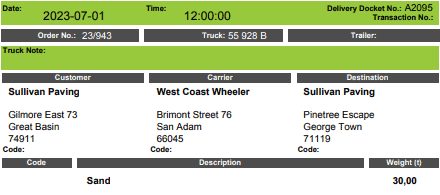

DELIVERY DOCKETS

Print the delivery docket for your customer or automatically send it to your customer emails.

You can easily set up the delivery note header and footer for each of your loading sites.

If your Load ‘n Sign service is active you will find then the delivery docket signed by the truck driver who received the material. To activate Load ‘n Sign go to Active Services into the upper right sandwich menu. The truck driver must download the Load ‘n Sign APP in his smartphone.

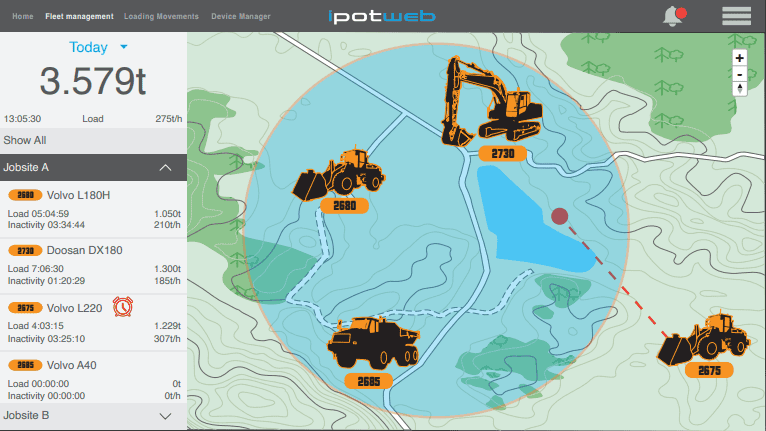

FLEET MANAGEMENT

A map of your loading site showing where each machine is. An alarm message will be sent when one goes out of the geofence you have created.

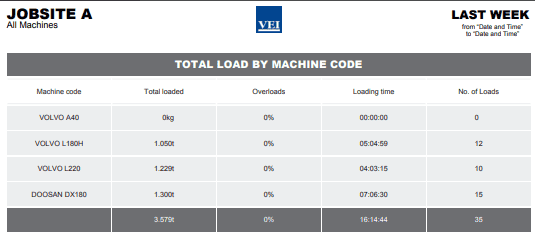

LOADING SITES

A resume of loaded weights by day, week, month or year together of total loading time and inactivity gives you an overview of each machine operativeness.

Loading reports for each machine, loading site or all of them can be printed, having on hand vital data of machines and loading sites performances, production and sales.

AUTOMATED REPORTS

Automated reports can be set accordingly to your needs to be sent on a specified time of the day and email address.

You choose from the filters you have set, choose the Loading site or all of them, select the type of file, .csv, .xlsx, .pdf, enter the emails to whom you want the report to be sent to and click CREATE; job is done, recipients will receive a bunch of vital data for analysis, sales and invoicing purposes, setting automatic imports into your ERP system.

AUTOMATIC FORWARDING

Automatic forwarding can be used to send the raw data received from the weighing device to a remote server. Without any filter and or interpretation by ipotweb, data can be sent immediately after reception in order to have your FTP or HTTP site always with data in real time.

Specifications

| specifications | s |

|---|---|

| power supply | 9÷36Vdc |

| working temperature | -40÷+80°C |

| shocks | 40G |

| device/sensors protection | IP54/IP67 |

| size | 140x204x67 |

| display | HD color |

| measurement error | 3% |

| legal for trade | no |

| data management | s |

|---|---|

| production monitoring(products) | 30 |

| tons/hour | yes |

| # of daily trips | yes |

| destinations | 20 |

| daily total | yes |

| cloud connection | USB-wireless |

| loading file download (.csv) | yes |

*see products datasheet for complete details