1. Why Axle Group Weighing Is Critical Under NZTA WIM Enforcement

-

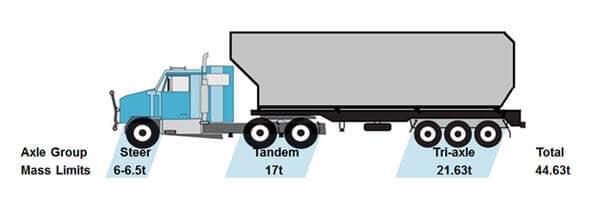

New Zealand’s Vehicle Dimensions and Mass (VDAM) Rule specifies exact limits for each axle group single, tandem, or tri-axle as well as total gross weight. Exceeding any axle-group limit, even if the GVM is within legal maximum, can trigger enforcement actions.

-

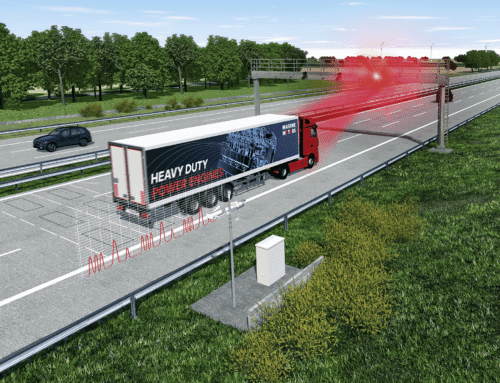

WIM systems installed at freight corridors including SH1 at Bombay Hills capture axle load data while vehicles are in motion. Authorities match weight readings with ANPR to detect overloaded axle groups, not just gross weight. Vehicles flagged may be fined or invoiced even without stopping, depending on enforcement rules.

⚙️ 2. How Loadsense On-Board Systems Work in NZ Configurations

Sensor Installation & Suspension Types

-

Airbag suspension vehicles: Loadsense uses pressure sensors connected per levelling valve on each axle group. These deliver real-time axle weight readings to the cab or mobile app.

-

Mechanical (leaf‑spring) suspension: Loadsense installs deflection sensors to measure axle displacement under load ideal for rugged logging or construction trucks with high durability and shock resistance.

The Loadsense Integrator & Display

-

The system central Integrator communicates via RF wireless (not just Bluetooth) to the in-cab display or mobile app. Supports up to two mobile devices simultaneously, enabling both driver and loader or dispatch view access up to 50 m away.

-

It supports a mix of sensor types air, mechanical, strain gauges, load cells across truck and trailer combinations (e.g., mixed suspension setups) under a single system.

Calibration Process

-

Place the vehicle/trailer empty on a certified weighbridge to record tare axle group weights.

-

Load to maximum legal capacity, then weigh again.

-

Enter tare and loaded weights into the Loadsense system to create a calibration curve.

-

Real-time interpolated weight readings then deliver highly-accurate axle group weights under all loading conditions.

3. Real-Time Use Case Examples in NZ

Kenworth, MAN, DAF, Hino, Scania Fleets

-

Loadsense installs tailored sensor setups for different truck brands. For example:

-

Kenworth T610, K200, C509: airbag or spring setups supported, including B‑train trailer combos.

-

MAN TGX/TGS and DAF LF/CF/XF: compatible with NZ air or mechanical suspension types and commonly used in NZ’s freight and construction sectors.

-

-

Applications include:

-

Logging & forestry trucks encountering variable off-road loading.

-

Tipping trucks with shifting loads.

-

Livestock and bulk tankers, where liquid movement affects axle loads.

-

Owners can distribute or adjust load prior to highway departure, avoiding WIM-triggered enforcement.

-

4. Avoiding Fines with Accurate Axle Group Weight Compliance

-

WIM enforcement now detects axle group overloads instantly, even at speed. Fines can be deployed automatically and may not involve stopping the truck. The margin for error is minimal.

-

Fines are issued based on static weighbridge confirmations, often at CVSC after flagging. Violations carry per‑axle‑group penalties, which can be several hundred to thousands of NZD depending on the degree of overload and repeat offences.

-

Repeated breaches can harm your Operator Rating System (ORS), lead to permit suspension (such as HPMV or 50MAX), and trigger corrective action or investigation. Loadsense provides documented proof of weight management operations to defend your compliance credentials.

✅ 5. Benefits Recap – Why Loadsense Adds Value for NZ Fleets

-

Real-time axle group weight data helps load smarter and ensures compliance from the yard or on-site before WIM zones.

-

Accurate for both gross and individual axle limits, protecting against instant WIM‑triggered fines.

-

Flexible sensor architecture adapts to various suspension types and mixed truck-trailer combinations.

-

Local NZ compliance and support: installation, calibration, servicing and fleet integration tailored to Kiwi rule sets.

-

Operational efficiency: eliminate weighbridge delays, optimise payload, minimise vehicle wear and tear.

Technical Summary Table

| Feature | Details |

|---|---|

| Suspension Compatibility | Airbag and mechanical spring sensors, mixed combinations |

| Display & Reporting | In‑cab screen, mobile app (RF wireless), fleet telemetry integration |

| Calibration Method | Tare + full load weighbridge calibration for interpolated accuracy |

| Axle Group Monitoring | Steer, drive, trailer axle groups measured independently |

| WIM Enforcement Protection | Pre‑trip compliance avoids WIM-flagged infractions |

| Regulatory Impact | Protects ORS rating, permits (50MAX/HPMV), avoids RUC penalties and overloaded fines |

| Operational Benefits | ROI via time saved, payload optimisation, reduced maintenance costs |

| Support & Setup | NZ-based installation, calibration, and ongoing service |

With WIM deployment intensifying on SH1 including upcoming permanent systems at Bombay Hills truck operators have less room for error in axle group loading. Loadsense onboard weighing systems are built specifically for New Zealand conditions, ensuring that you stay compliant with NZTA axle group rules, avoid penalties, and drive with confidence.

Need detailed fine‑amount threshold tables by axle group, or a vehicle‑specific Loadsense installation quote? I’d be happy to provide, tailored to your truck setup.