Introducing WIM at Bombay Hills (SH1 North & Southbound lanes)

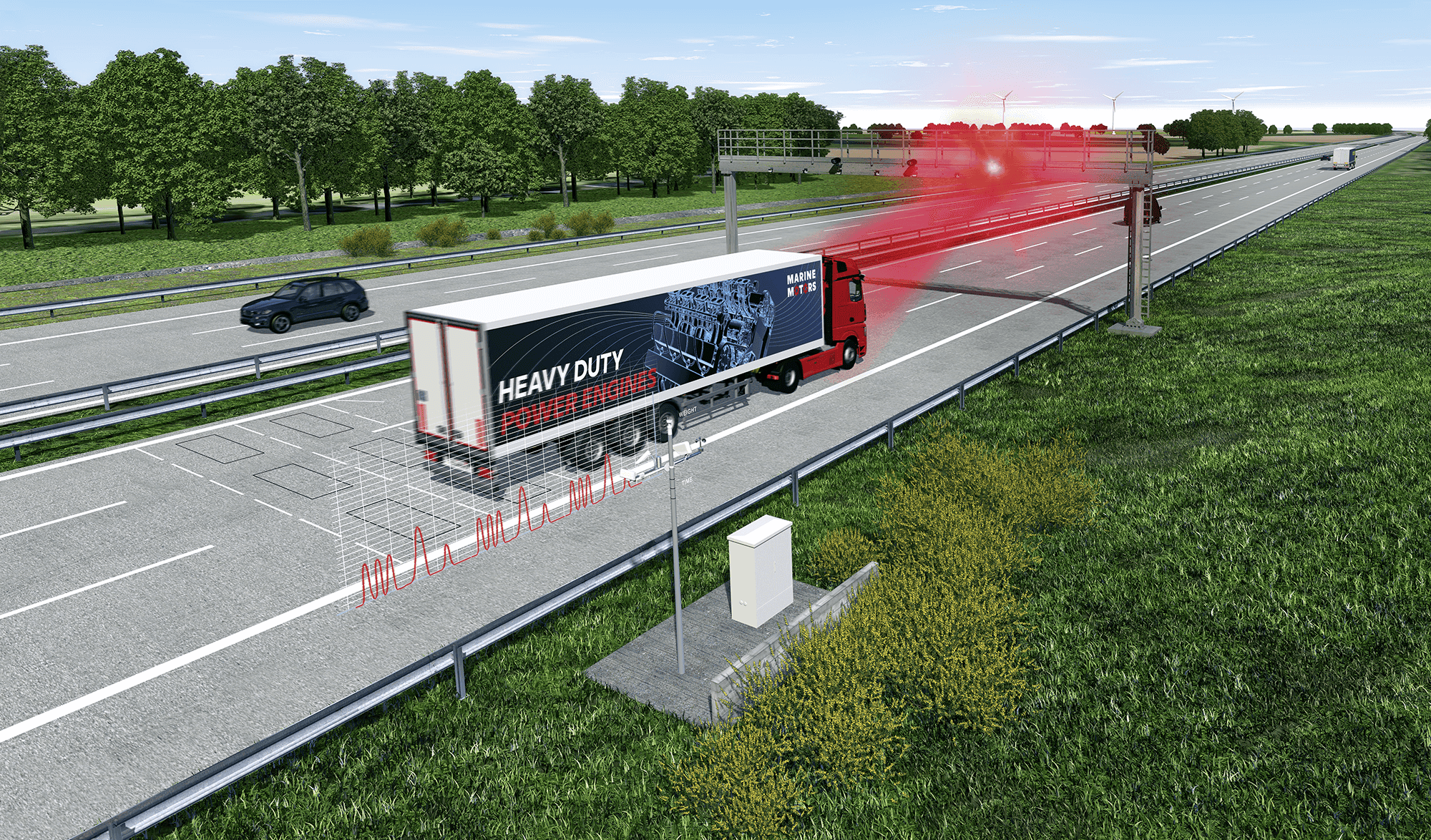

Waka Kotahi NZ Transport Agency (NZTA) is rolling out in‑road WIM sensors at the SH1/SH5 interchange just north of Bombay Hills, with installations in both northbound and southbound lanes leading toward the Commercial Vehicle Safety Centre (CVSC) in Waikato/Bay of Plenty.

These in‑road scales, paired with asphalt cuttings installed to precise levels, will screen passing heavy vehicles in motion, linking axle weights, vehicle classification, and number‑plate recognition. Vehicles flagged as potentially overloaded are directed by electronic signage into the CVSC for static weighbridge checks and further compliance inspection.

This is part of NZTA’s national Commercial Vehicle Safety Programme (CVSP) (formerly the Weigh‑Right Programme), which aims to enforce axle and gross vehicle weight limits across major freight corridors, supporting safer roads and fairer transport industry regulation.

How WIM Systems Work

1. Road-Embedded Sensors

WIM technology uses piezo‑electric or strain sensors embedded in grooves cut into the pavement. These sensors detect the pressure or deformation from each axle as a truck drives over them at normal traffic speeds (~90 km/h), converting dynamic loads into estimated static axle and gross weights.

2. Inductive Loops & Vehicle Classification

Sensors include inductive loops that detect vehicle entry/exit, measure axle spacings, vehicle length, speed, and classify vehicle types (e.g. rigid vs. combination).

3. Central Processing & ANPR Integration

Data flows into a processing unit that aligns sensor output with Automatic Number Plate Recognition (ANPR) images, comparing weights against legal limits defined by NZ’s Vehicle Dimensions and Mass (VDAM) rules including limits for single, tandem, and tri‑axle groups.

4. Screening & Signage

If a truck exceeds legal limits, its plate is displayed on an electronic sign directing the driver to stop at the CVSC. Otherwise, compliant vehicles can continue without interruption.

5. Static Weighbridge Enforcement & Fines

WIM provides pre-screening only. Official weight determination and fines are still issued using static weighbridge readings at the CVSC or roadside weighbridges. NZ Police Commercial Vehicle Safety Team (CVST) officers handle enforcement and further checks not the WIM system itself. A vehicle flagged by WIM will be pulled into side‑lanes and weighed to verify overloading.

⚖️ WIM Enforcement: Fines & RUC Invoicing

-

Static weighbridge readings are used to issue any fines for overloaded vehicles, including per‑axle and axle‑group offences. WIM data alone does not trigger fines directly.

-

Road User Charges (RUC) invoices may also be generated based on WIM‑derived data where unpaid or under‑declared RUC is identified, particularly for repeat offenders. These RUC invoicing cases are separate from weight‑based fines but can occur on the same trip.

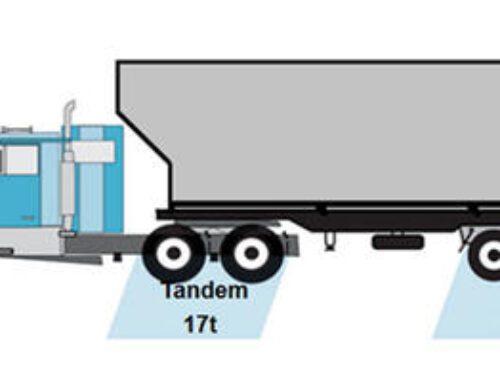

Understanding NZ Axle‑Group Limits & Fines

Under NZ’s VDAM Rule, allowable weights are strictly defined for:

-

Single axles

-

Tandem axle groups

-

Tri‑axle groups

Even if a vehicle’s gross weight is within the allowable limit, overloading a specific axle group (e.g. tandem) can result in a fine. Operators must consult certified loading documentation and consider axle spacing, tyre pressures, and vehicle tare weight to ensure compliance.

Fines can range from several hundred to thousands of dollars per axle group violation. Repeat breaches can also affect permitting (e.g. 50MAX or HPMV), Operator Rating System (ORS) performance, and result in permit revocation, immobilisation, or the loss of access to higher RUC types.

✅ How Loadsense On‑Board Axle Scales Help

To avoid costly WIM‑triggered fines, many operators are installing on‑board, real‑time axle group weighing systems such as those offered by Loadsense:

-

These systems measure individual axle group weights (single, tandem, tri‑axle) in real time, from inside the cab or via mobile app, using sensor types suited to airbag or mechanical suspension setups common on Kiwi trucks and trailers.

-

Operators can load within allowable limits before departure, even when multiple axle groups are used or trailer combinations change.

-

Loadsense helps maintain correct RUC declarations, meet permit conditions (50MAX, HPMV), and protect ORS operator ratings by avoiding fines and re‑audits.

This proactive compliance tool also enhances:

-

Payload optimization

-

Operational safety and reliability

-

Reduced downtime

-

Reputation management in a fully regulated environment

Summary Table

| Topic | Key Insight |

|---|---|

| WIM Location | SH1 North & South lanes at Bombay Hills, leading to CVSC |

| How WIM Works | Embedded pavement sensors, ANPR, classification, pre‑screening |

| Enforcement Mechanism | Static weighbridge fines in CVSC, not automatic WIM |

| Legal Limits | Gross weight + per-axle group under VDAM rules |

| Operator Risk | Fines, RUC invoicing, ORS, permit consequences |

| Loadsense Benefits | Live axle data, avoid fines, improve compliance, protect reputation |

Final Thoughts

The new WIM systems at the Bombay Hills CVSC site exemplify NZTA’s move toward automated, dynamic enforcement of vehicle loading rules. While this technology streamlines monitoring and pre‑screening, the actual legal weight determinations are firmly rooted in static weighbridge readings.

For operators hauling freight on NZ’s state highways particularly around SH1 on-board axle group weighing systems from Loadsense offer essential real‑time feedback to stay within VDAM limits and proactively avoid penalties. In a landscape where both fines and RUC invoicing can accrue from single axle group overloads, good load management is no longer optional it’s a core part of compliance strategy.

[…] Home » Blog » Why Axle Group Weighing Is Critical Under NZTA WIM Enforcement – Loadsense Scales Previous […]