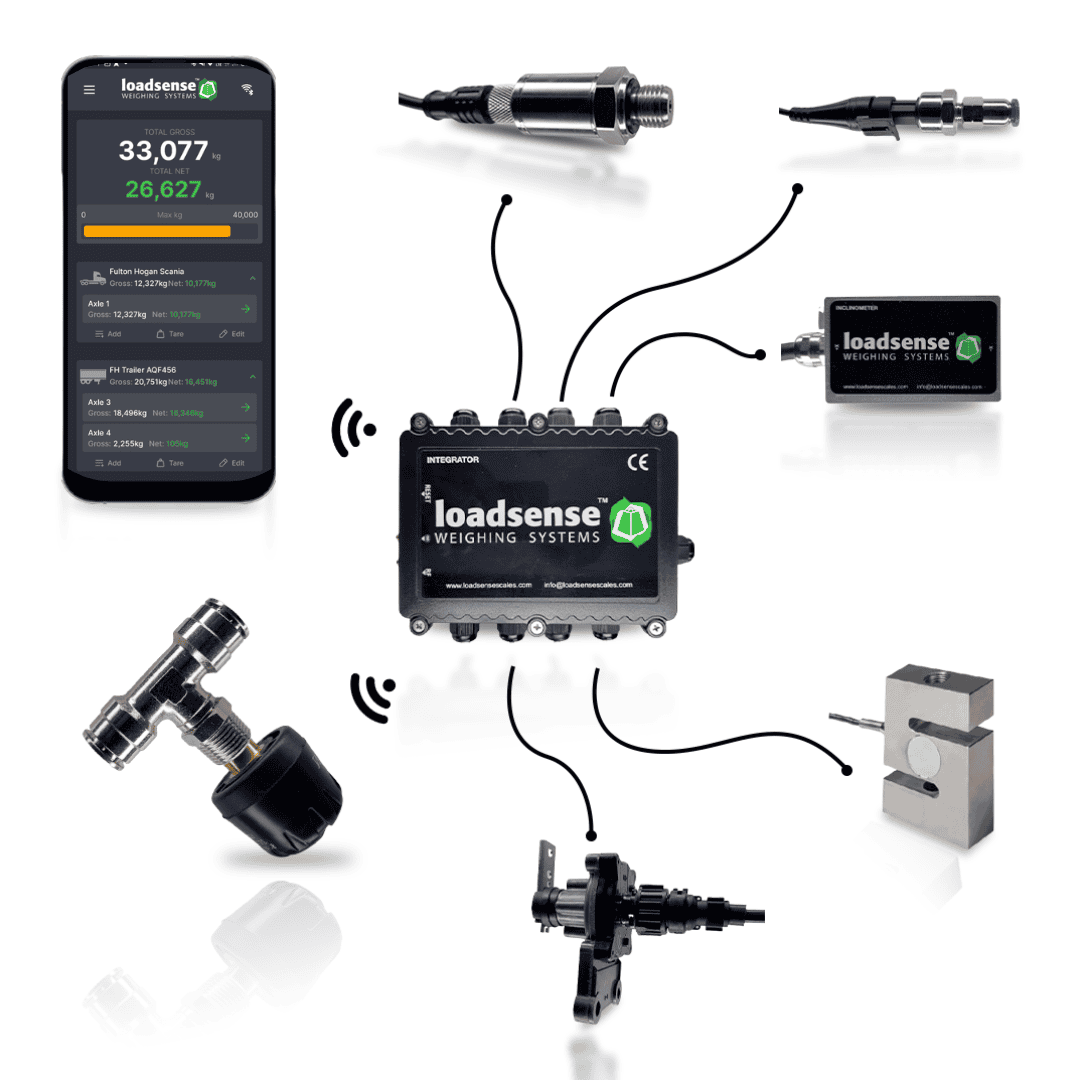

Loadsense has developed a unique on-board air suspension scale which has air pressure sensors fitted to the airbags of Trucks and Trailers.

The Loadsense onboard air suspension scale comes in two variants in terms of the type of air pressure sensors used. These two types of air pressure sensors are:

- Wired Air Pressure Sensor

- Wireless RF Air Pressure Sensor (Not Bluetooth)

The wired Loadsense air pressure sensor on trucks and trailer airbags works by continuously monitoring the air pressure within the airbag system, which is critical for maintaining proper ride height, load distribution, and suspension performance. Here’s how it generally functions:

- The Loadsense Wired Sensor Placement: The sensor is usually installed on the airbag or in close proximity to the air suspension system. It is connected to the airbag through a small port that allows it to measure the air pressure inside the airbag.

- Measurement Mechanism: The sensor typically contains a diaphragm or piezoelectric element that deflects or generates a small electrical signal when subjected to air pressure. The amount of deflection or the signal generated is directly proportional to the pressure inside the airbag.

- Signal Transmission: The sensor converts the mechanical pressure into an electrical signal, which is then transmitted through wires to the vehicle’s control unit or dashboard. This wiring ensures a stable and reliable transmission of data.

- Data Processing: The vehicle’s control unit processes the signal to determine the exact pressure in the airbags. This data can be used to adjust the air suspension system automatically or provide information to the driver about the current status.

- Feedback and Adjustment: If the system detects that the pressure is too low or too high, it can trigger adjustments, such as inflating or deflating the airbags to maintain the optimal pressure. This is crucial for ensuring a smooth ride, proper load distribution, and preventing damage to the vehicle.

- Driver Interface: Some systems may include a display on the dashboard where the driver can see the current air pressure readings. Alarms or warnings may be issued if the pressure falls

outside the recommended range.

outside the recommended range.

Overall, the Loadsense wired air pressure sensors in trucks and trailers weighing are essential components that contribute to the safety, stability, and efficiency of the vehicle’s suspension system.

The wireless Loadsense RF (Radio Frequency) air pressure sensor on trucks and trailer airbags works by monitoring the air pressure within the air suspension system and transmitting this data wirelessly to a receiver or control unit. Here’s how it typically operates:

1. The Loadsense Wireless RF Sensor Placement: The wireless sensor is attached directly to the airbag or connected to the air suspension system. It measures the air pressure within the airbag, similar to how a wired sensor does, but without the need for physical wires to transmit data.

2. Pressure Measurement: The sensor contains a pressure-sensitive element, such as a diaphragm or a piezoelectric material, that detects the air pressure inside the airbag. When the air pressure changes, this element reacts by producing a corresponding electrical signal.

3. Signal Conversion and RF Transmission: The electrical signal generated by the pressure-sensitive element is then converted into a digital signal by the sensor’s internal electronics. This digital signal is transmitted as a radio frequency (RF) signal.

4. Wireless Communication: The RF signal is transmitted wirelessly from the sensor to a receiver installed in the vehicle. The receiver can be part of the vehicle’s onboard control system or a dedicated monitoring device.

5. Data Processing: The receiver captures the RF signal and decodes it to extract the air pressure information. The control unit processes this data to determine the current air pressure within the airbags.

6. System Feedback and Adjustment: Just like with wired sensors, the control system can use the pressure data to adjust the air suspension system automatically. If the pressure is too low or too high, the system may inflate or deflate the airbags to maintain the correct pressure.

7. Driver Interface: The data can be displayed on the vehicle’s dashboard, allowing the driver to monitor the air pressure in real-time. Wireless systems may also trigger alerts if the pressure is outside the optimal range.

8. Power Supply: Wireless sensors are typically battery-powered, with low power consumption to extend battery life. Some advanced systems may use energy harvesting techniques, such as using the vibrations of the vehicle to generate power.

9. Advantages

- Ease of Installation: No need for extensive wiring, making installation simpler and faster.

- Flexibility: Easier to retrofit on existing vehicles without modifying the wiring.

- Reliability: Reduces the risk of wire damage or failure, which can occur in harsh environments.

In summary, the Loadsense wireless RF air pressure sensor provides a convenient and efficient way to monitor airbag pressure when weighing in trucks and trailers, enhancing vehicle safety and performance while offering flexibility in installation and maintenance.

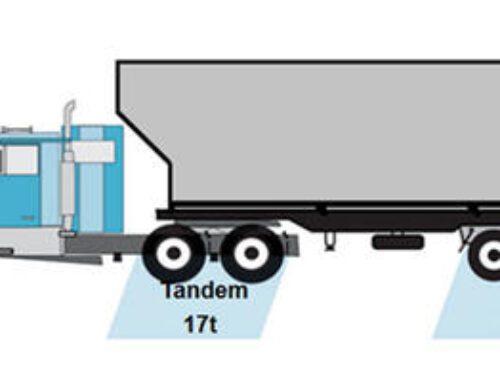

[…] Weighing for Truck and […]

[…] ✅ Onboard Weighing for Air Suspension […]